Sometime towards the end of last year I started drawing more. At first it was polite doodles on printer paper before I fell asleep at night. It has since spread to most hours of the day, not that I can draw that often, but the lines and weights and colors of everything absorb most of my attention. Maybe this is a result of introducing quinoa into my diet. In any case, I want to be able to convey their presence!

I assembled a tripod easel thing to aid me on my quest. This has been done thousands of times before, we all have our own little nit-picky needs to fulfill. I think there are even commercially available pochade boxes that attach to a tripod, and french easels, and tripod easels. I wanted something stout and that enabled me to rotate the paper.

Below, I made this aluminum mounting plate which has a piece of HDPE sheet screwed to it. If it's damp out I'll probably use this work surface. Maybe I'll screw something else to it if I have any ideas.

Here is a larger wooden surface with a beech dovetail that fits in the slot on the tripod head just like the other mounting plates. I will use this for large sheets of paper, 11x15" or so.

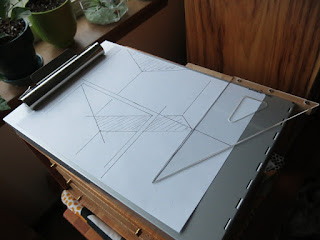

Lastly, for supporting the habit of drawing bedside, I attached a mounting plate permanently to the aluminum clipboard with solid brass rivets:

Here is the tripod ballhead in all its beaming whiz-gizmo. I'll inform you and the governor if I ever use the bubble levels on it.

Bonus content for your persistence. When looking out this window, through the bug screen, at the chain-link fence nearly a block away, an interference pattern is formed. The pattern is the same as the chain-link fence, but magnified! If the observer has good vision, it's not noticeable, but by blurring the eyes (or setting the camera to focus at ~50cm and turning the f-stop up) it becomes visible. The image is distorted corresponding to the inaccuracies in the screen mesh; the weft is not perfectly level and straight (if you will). The mesh also magnifies other patterns.