Sunday, January 26, 2014

Craft Knife Proposal

This is a drawing I made of a craft knife that I'd like to machine but don't have the tooling for. It's based on a knife made by Olfa. I originally posted with the intent to make a small batch of these for sale, but it would be too much an undertaking for me alone. If anyone in the future is interested in this, I'd like to hear from you!

The jaws would be made of tempered O1 or A2 steel, the grip of 303 stainless, and the stem of the handle would be brass. The grip pattern itself could take on many forms, but I was imagining something similar to the drawing.

In case you're curious, the drawing was done on my little drafting board in pencil.

Tuesday, January 21, 2014

Bridge Update

Well, she did alright. It held 87 pounds*, and it weighed 16.8 grams** itself. This meant an efficiency of 2350:1. The good news is that this was better than anyone at the school. The bad news is the runner-up's bridge had an efficiency around half of hers, so she's got to make a second one for the regional competition.

*weights from the gym

**scale from the chemistry room

Saturday, January 18, 2014

Hand Warmers Etc

I made this pattern and sewed these.

They hold bags of rice, which are microwaved to warmth.

The pockets act as insulation, and can be washed if the cold paws are also dirty ones.

Not a stitch is showing. Even the bottom of the liner is hand-stitched so the thread is hidden.

I made this, though I'm not entirely sure why. Inside is nothing but a 7-segment LED module. Unlit, of course.

And some food. Important too.

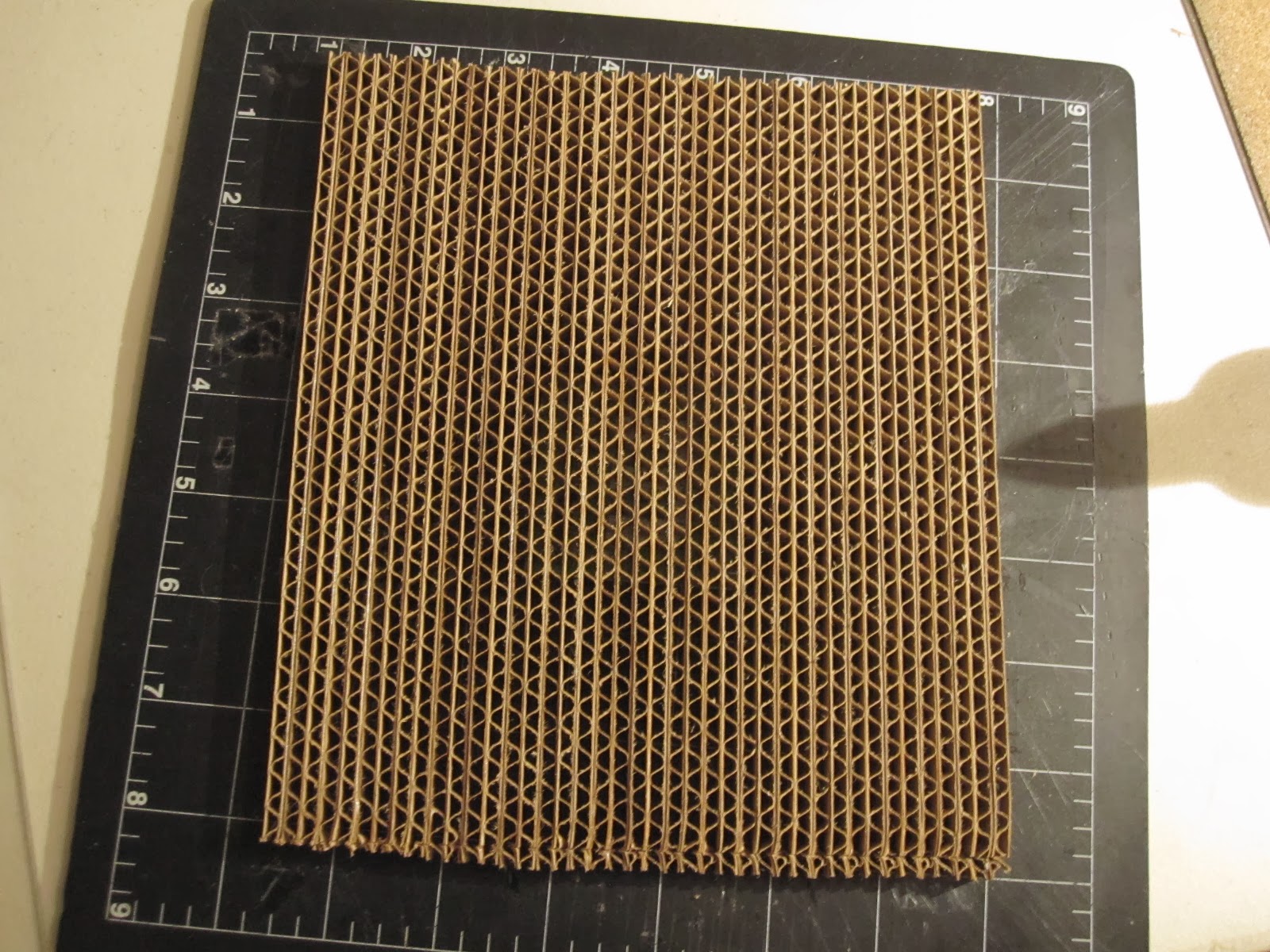

I gave the honeycomb sandwich another go, this time with some degree of success. Made with strips of corrugated cardboard.

Useful? Eh! I'll know how to make it when I need it, though.

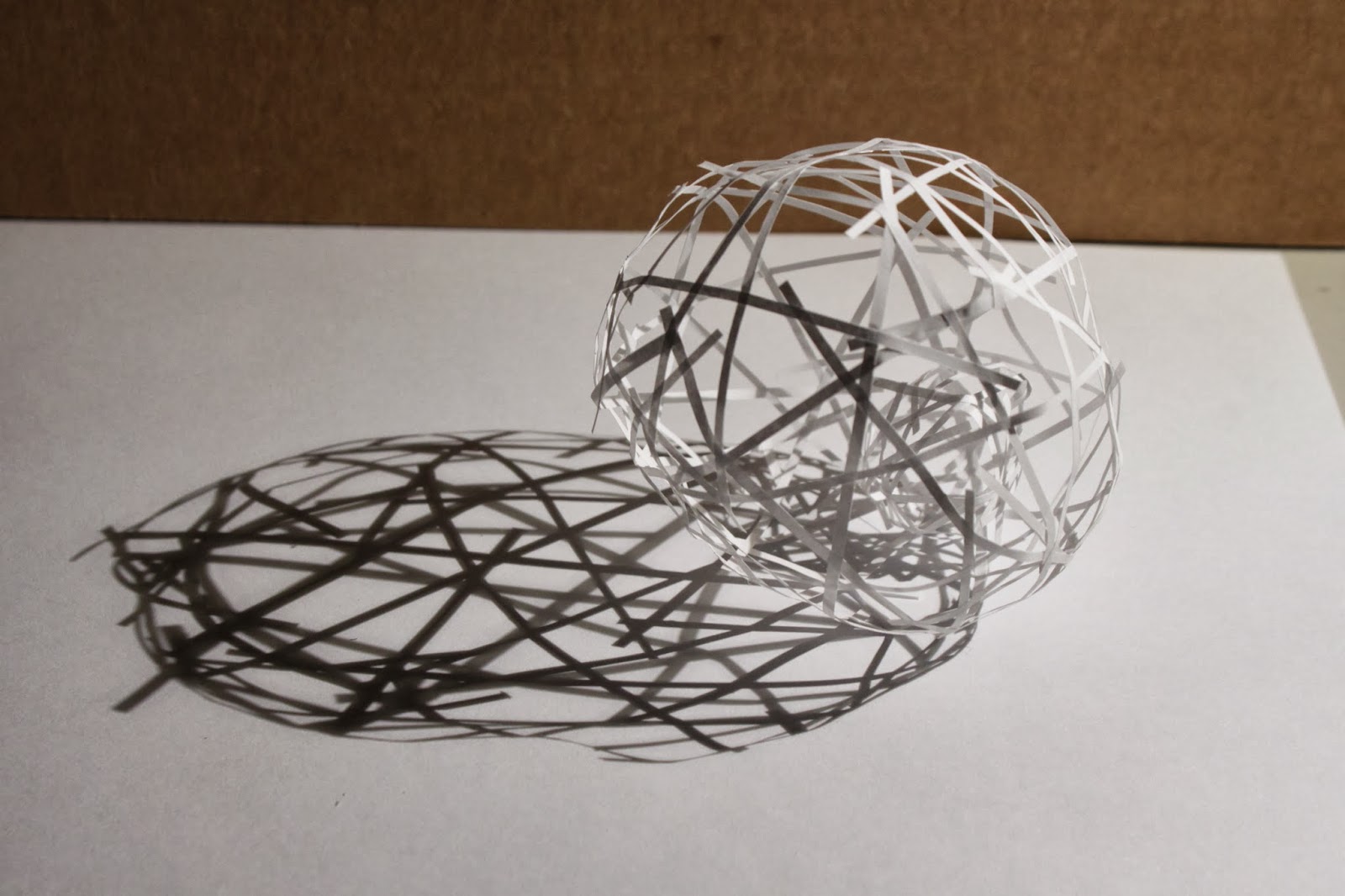

Bridge Building Competition Bridge

My sister Quinn, and I built this bridge for a competition at her school. I made a similar one four or five years ago for the same competition. It wasn't this nice, though. It also had different requirements for design.

She's required to break it since we can't be bothered to make another. I think it'll hold lots of weight though; at least 80 lbs.

The loading point (above).

Almost all the joints are lap joints of some type. There are very few butt-joints. We notched them using a scalpel, needle files, and a jeweler's saw. It's hard to tell all the work that went into it, because you can't tell a lap joint from a butt joint by looking at it from only one side.

Above is a picture of the loading surface, as seen from above. The 3/8" rods go though the bottom of the bridge to connect to the weights on the left and right of the 'canoe.' The loading plate only goes on one side, not both at once.

One photo mid-construction.

Stay posted to see how much this bridge holds.

The loading point (above).

One photo mid-construction.

Stay posted to see how much this bridge holds.

Subscribe to:

Posts (Atom)