I made a metal shuttle for use in conjunction with the awl. It works well. I will include an aluminum one with awls sold on Etsy.

Sunday, October 26, 2014

Metal Awl Shuttle

Monday, October 13, 2014

Mk. III, Number Two

This is the awl I made to keep. Brass body.

It's already working hard, patching jeans:

A video of the awl in use is coming. The first Mk. III awl is now for sale on Etsy.

Thursday, October 9, 2014

Mill Motor and Pulleys

The large pulley is made of solid maple. I turned the OD on the wood lathe, and the ID on the metal lathe with a vacuum next to the cutter. The small pulley, and bushing inside the large pulley are made of delrin. The white tube in the upper right contains the run capacitors and a leprechaun.

Above, a fuller view. Below, you can see the bottom of the bushing that interfaces the pulley with the spindle. There are two 4-40 clamping screws, radially symmetrical. 90º from the clamping screws on the flange are 1/16" dowel pins, parallel with the spindle. These stick up into the wooden pulley to prevent slippage. I could have made the wooden pulley press-fit on the spindle, but I thought it would crack over time. It probably will anyway, but there was no decent plywood around. The wooden pulley ID is a slip fit onto the bushing. The delrin motor pulley is a press-fit.

Below is the first iteration of drive belt. It's made of a bicycle inner tube. It won't last forever but it works for now. Maybe a piece of thin leather will find its way into my hands by the time it breaks. If not, there is a steady supply of inner tube rubber. The pulley ratio ended up bringing the no-load RPM to 490 RPM. The motor can put out about 25 watts of power. I'm certain that a 16" bastard file could remove metal more quickly, but a 16" bastard file can't drill bolt patterns.

Above is the enclosure mounting bracket, also made of 3/4 maple. Made it with a jeweler's saw! Took a while.

Here is a video of it working:

Thursday, October 2, 2014

Japan Flag

I made this for a friend... I had the colors left from a futsal flag. Sorry Canada. It's double-sided.

The sun has some irregularities, which are intentionally representative of solar weather. Mhmm. It would be cleaner if I could sew it with a zig-zag without the end tucked, but it wouldn't be as strong and I don't have a zig zag machine. Regardless, I think it looks a lot better than a printed/dyed flag. It has depth.

I cut these hanging strips on the bias, sewed them, and inverted them with a long wire hook made of RG45 welding rod.

Tuesday, September 30, 2014

Taig Mill Motor Mount

I made a mount for a new motor for my Taig milling machine. The motors that taig offers (I bought both) are overpowered and too heavy for the mill. Their large mass cantilevered out from the mill head amplifies chatter, especially when cutting along the Y axis. It puts a lot of strain on the leadscrew and head. The weight deflects the head downwards, and it adds another dimension of difficulty when trying to hold tolerances.

For a long time I powered the mill with a small used 230v fan motor running on 115v, which was superior in every way but power. It is German made and has very low vibration. I only used one pulley ratio with it, around 400 RPM. The low speed is well suited to the mill; it keeps chatter at bay. The motor could be stalled with a 1/8" end mill though, to get an idea for how weak it was. In the past, I have regularly switched between all three motors. The fan motor couldn't drill a 1/4" hole and I'm pretty sure a file can make chips faster, but it left the best surface finish. The cheap motor from Taig had terrible vibration which transferred directly to the work, but had the speed and power to spin a 1/4" drill. The upgrade motor from Taig was a compromise between the two, but it spun so fast that it struggled with cutters over 3/16".

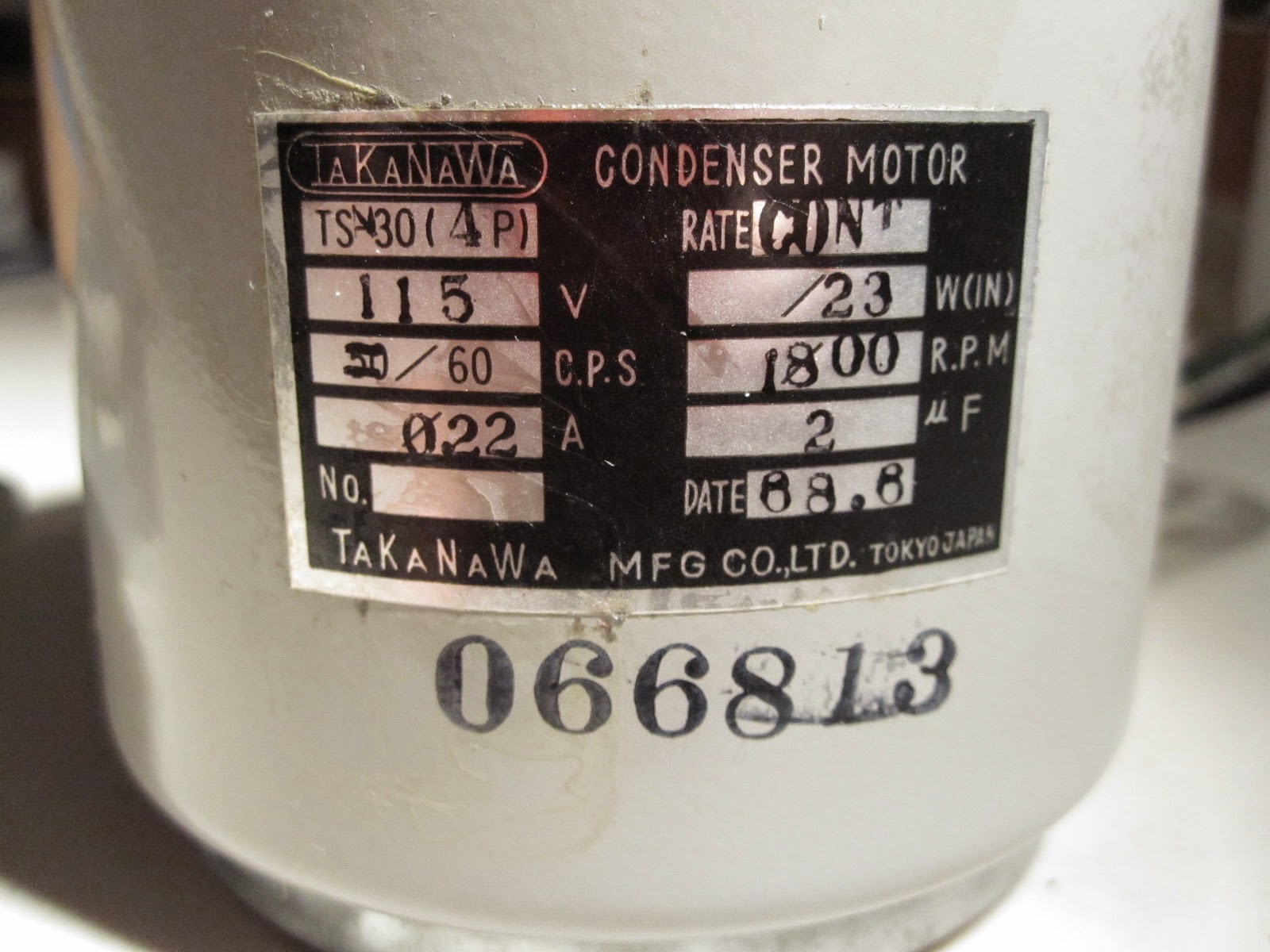

As much as I want to be done fighting the Taig mill every step of the way, I don't know what I'd do without it. Another mill is out of the question. I decided it was worth putting a bit of time into getting the motor situation rectified. I bought a Takanawa condenser motor from an electronics surplus site for $20. I browsed all the AC motors of maybe five surplus sites, and decided on this one.

It looked like it ran smoothly, had a relatively low RPM, and it was cheap. I confirmed today that it does indeed run very nicely. It probably has twice the torque of the fan motor I was using previously. I'm going to run it with a flat belt and crowned pulleys instead of the Taig V belt, in interest of preserving as much of the motor energy as possible. The speed will be reduced to 400 RPM or so.

Below is the bracket that attaches to the side of the mill head:

And here is the plate that attaches the motor and allows it to slide for tensioning the belt:

See the motor mounted on the Taig Head here.

I will likely make another post when the pulleys and wiring are complete. The run capacitors are going inside a PVC pipe enclosure. For shits and a good time, I cleaned up a PVC end cap:

It looks nice but takes a while. These are my tools:

For a long time I powered the mill with a small used 230v fan motor running on 115v, which was superior in every way but power. It is German made and has very low vibration. I only used one pulley ratio with it, around 400 RPM. The low speed is well suited to the mill; it keeps chatter at bay. The motor could be stalled with a 1/8" end mill though, to get an idea for how weak it was. In the past, I have regularly switched between all three motors. The fan motor couldn't drill a 1/4" hole and I'm pretty sure a file can make chips faster, but it left the best surface finish. The cheap motor from Taig had terrible vibration which transferred directly to the work, but had the speed and power to spin a 1/4" drill. The upgrade motor from Taig was a compromise between the two, but it spun so fast that it struggled with cutters over 3/16".

As much as I want to be done fighting the Taig mill every step of the way, I don't know what I'd do without it. Another mill is out of the question. I decided it was worth putting a bit of time into getting the motor situation rectified. I bought a Takanawa condenser motor from an electronics surplus site for $20. I browsed all the AC motors of maybe five surplus sites, and decided on this one.

Below is the bracket that attaches to the side of the mill head:

And here is the plate that attaches the motor and allows it to slide for tensioning the belt:

See the motor mounted on the Taig Head here.

I will likely make another post when the pulleys and wiring are complete. The run capacitors are going inside a PVC pipe enclosure. For shits and a good time, I cleaned up a PVC end cap:

It looks nice but takes a while. These are my tools:

Friday, September 26, 2014

Awl Mk. III, Number One

Yesterday I finished the first awl of this version. Hopefully the pictures do it justice.

Everything is polished, adjusted, and fit to perfection. It has many improvements over Mk. II:

-Needle bar is more adjustable to fit your hand, and easily so

-Needle locking screw is recessed so thread cannot catch on it

-Spring is held centered by counterbores on thread tensioner, so it cannot interfere with the threads

-Knurled brass thumbscrew to retain bobbin holder

-Bobbin holder head is smaller to allow for easier thread rewinding

-All corrosion resistant metals: 6061 alu.; 302, 303, and 316 ss.; and 360 brass. It retained the little details of Mk. II that I liked:

-Stainless insert for bobbin holder thumbscrew

-Dowel pin to prevent thread tensioner from spinning

-Raised section on tensioner to keep sewing thread from interfering with threaded post.

-DBx1 needle and standard industrial bobbin

I'm selling these for $220 each. I will repair them as long as I am able in the unlikely event that it fails. They will be posted on my Etsy store.

Wednesday, September 24, 2014

Bookbinding Awl

For a friend. Alder body. PVC ferrule because it's what was lying around. M2 steel point, grooved, pressed, and epoxied in.

Subscribe to:

Posts (Atom)